Transfers, Adjustments & Additions

In this document:

Transfers

Transfer operations are when you are moving wine from one or more vessels to another. If you select multiple source vessels to transfer, they will be blended first before going into the destination vessels.

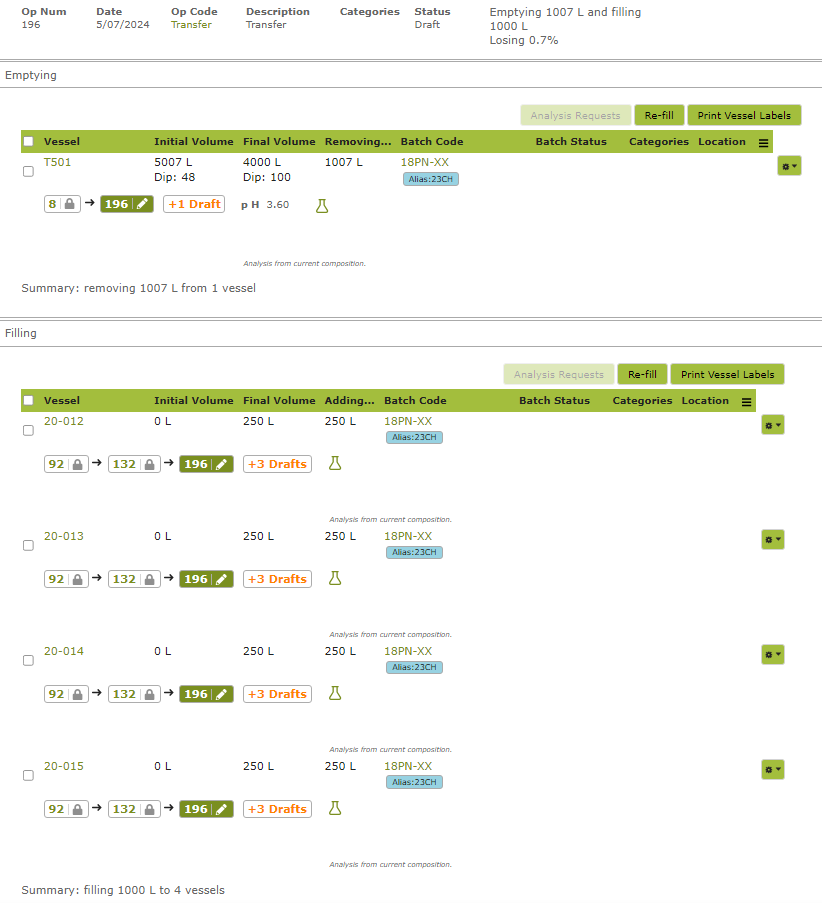

An example transfer operation filled out

Adjustments

Adjustment operations are used to perform an adjustment on the volumes in one or more vessels. This is generally used when you find that you need to change the volume but not because of any specific type of operation. For example, your vessel may have lost some wine because it fell over. Then your recorded volume would be incorrect and would need to be adjusted.

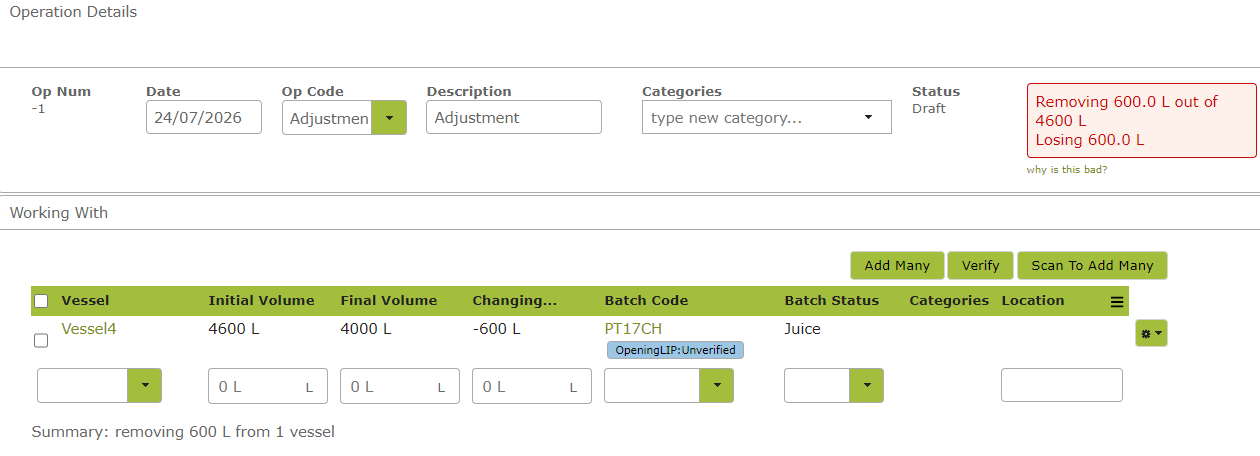

In an adjustment operation, you only see one table as you are not transferring the wine to other vessels

An example adjustment operation filled out.

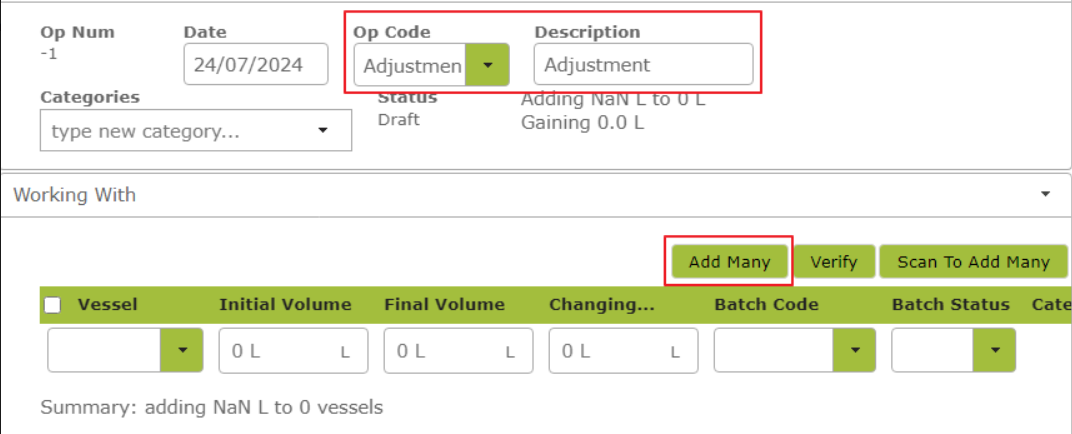

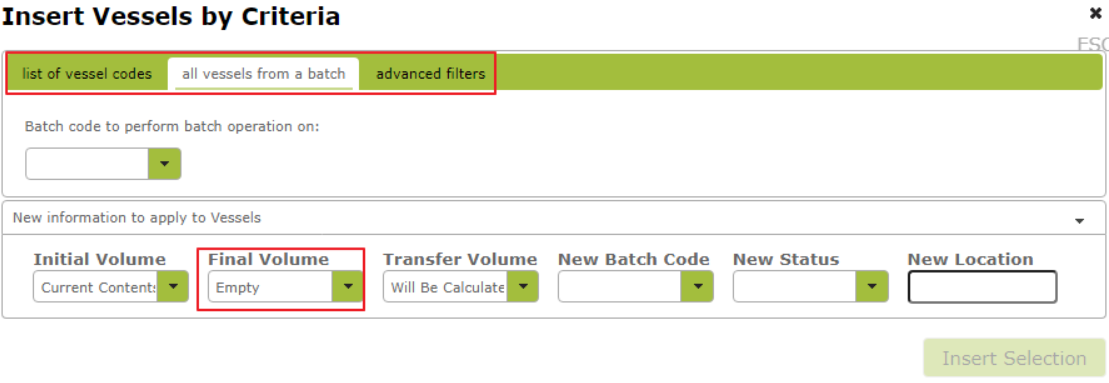

Emptying Vessels

Additions

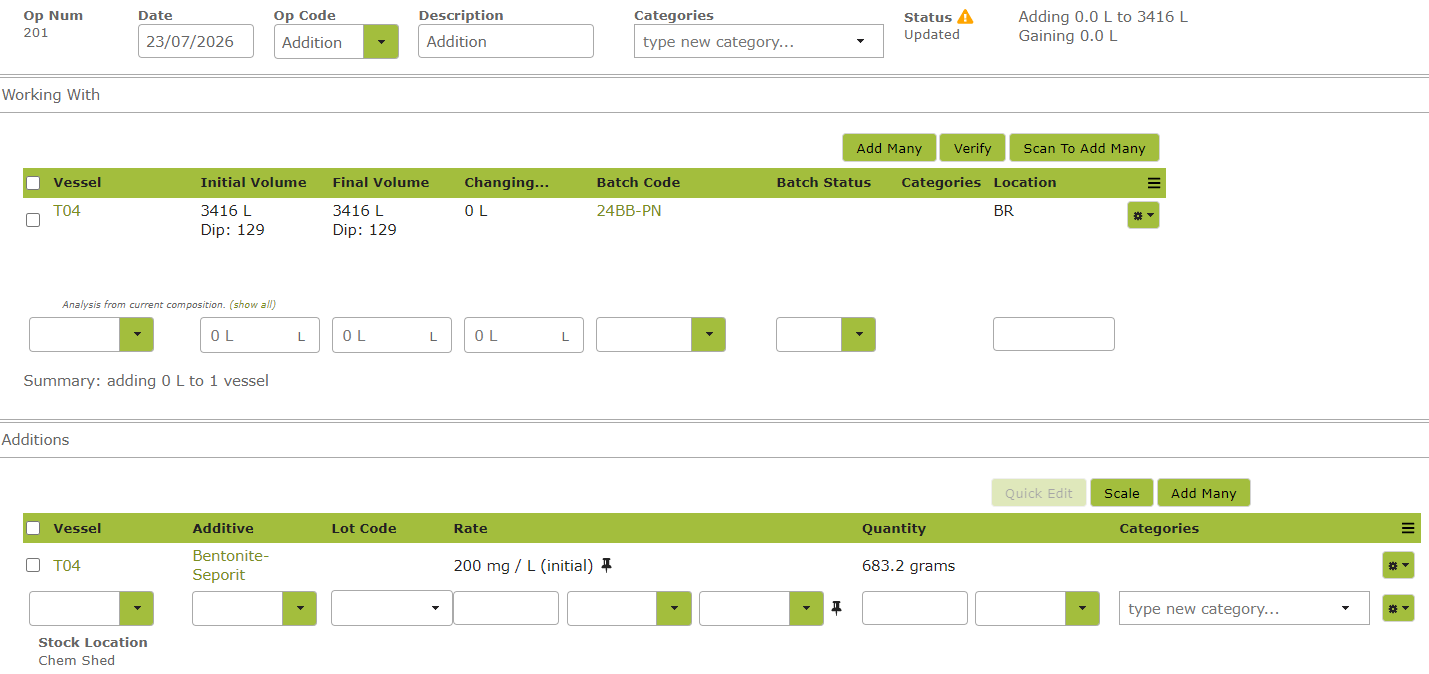

Addition operations are for when you add something to a vessel of wine, for example PMS.

To view an existing addition, click on the ‘Additions’ tab.

To create a new addition, click the ‘+ New’ tab. In the “Operation Details” area, select addition from the Op Code drop down menu. Then go to the “Working With” area and select the vessel(s) you want to work with. Then go to the “Additions” area to select the vessel you’re applying the addition to and the additive itself.

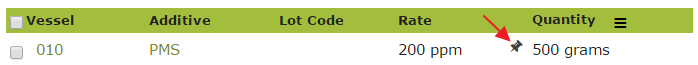

Enter the Rate to add, which will automatically calculate the Quantity.

Adjusting Initial Volume After Setting Rate or Quantity

When you enter/edit the Rate a ‘pin’ will appear in the Rate column.

This ‘pin’ simply indicates that the rate has been set and if you subsequently edit the initial volume in the vessel the rate will stay fixed while the quantity will adjust accordingly.

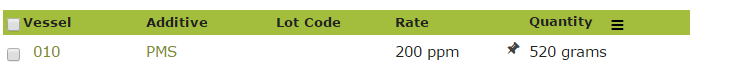

For example if you increase the initial volume in the vessel, the rate will stay fixed and the quantity will increase in proportion to the volume increase.

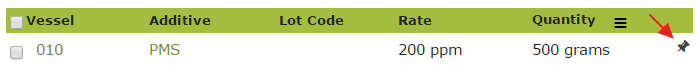

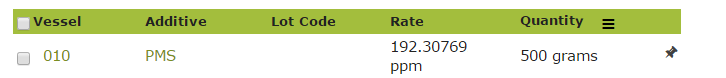

By contrast if you set a fixed quantity, the pin will appear in the Quantity column. If you now edit the initial volume in the tank, the quantity will stay fixed and the rate will change accordingly.

After change(increase) to initial volume. . .

Use the comments box to record safety or other relevant information.

If you are on a multi-location subscription, you can also set the location where stock will be depleted from by making a selection from the ‘Stock Location’ drop down menu.

You can also do additions on other operation types, for example, transfers.

Finally click ‘Save’ to create a draft or ‘Save and Update” to finalize the operation.

An example addition operation filled out.

Accounting for Bulk Losses

If when you empty or rack a tank, you end up with less than you started, the loss will show as a percentage at the top of the operation. If the loss is due to lees, and you do not recover or store the lees, then you should fully empty the tank, and the tank that you fill will recover less than you empty. The difference is a loss in volume. If you are using a subscription of that allows costing, then the costs will remain the same, but now that cost is spread across less volume, so the cost per litre or gallon will be slightly higher.

If you lose an entire vessel to spoilage, then there are a couple of choices, a) use an adjustment to empty the tank to zero, b) use a bulk despatch to empty the tank and have the other party be something like “spoilage” or similar. The second option makes it easier in reporting to see the value of the loss so that you can do a journal in your accounting system to write off this cost from Bulk inventory.