Opening The Movements Schedule

There are currently two areas in which you can open up the Stock Item Movements Schedule: the Stock Items List, and the Packaging Operations List.

If you are on the Stock Items list, you can select one or more Stock Items and click on the bulk action “review purchase schedule”. You will get a report based on the Stock Items you have selected.

If you are on the Packaging Operations list, you can select one or more Packaging Operations and click on the bulk action “review purchase schedule”. You will get a report based on any Additions that are scheduled for use on any of Packaging Operations you have selected.

Schedule Overview

Each Stock Item you are reviewing will have a section per Stock Location. In this example, we are reviewing stock levels at the “DEFAULT” location for two Stock Items, BOXES and SCREWCAP.

Each Stock Item you are reviewing will have a section per Stock Location. In this example, we are reviewing stock levels at the “DEFAULT” location for two Stock Items, BOXES and SCREWCAP.

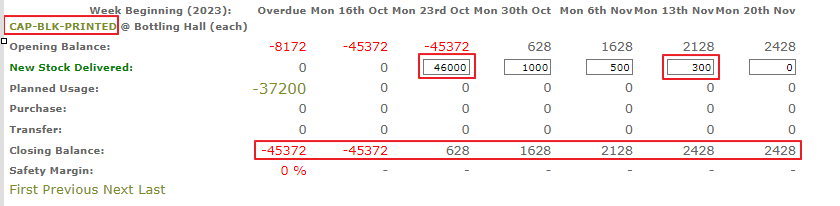

Each column represents all movements occurring within a given week. Opening and Closing balances let you see how much stock you start and finish with each week.

If a balance is negative, it will be shown in red.

Filtering Stock Items (Searching)

The options at the top of the Schedule can be used to show and hide different types of movement.

- Stock Location Code – Putting a location in this box will cause the Schedule to only show movements for a single location, rather than for all locations.

- Items With No Movement – Hidden by default. If you show these movements, you will be able to see all Stock Item, even if there are no planned movements for them.

- Items With Enough Stock – Shown by default. If you hide these movements, you will only be shown places where the stock is going to run out of stock in the upcoming weeks.

Ordering More Stock

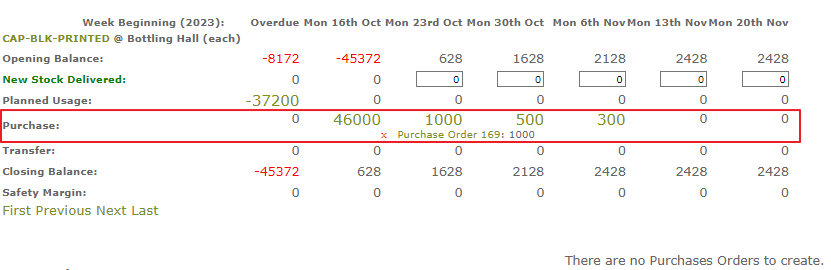

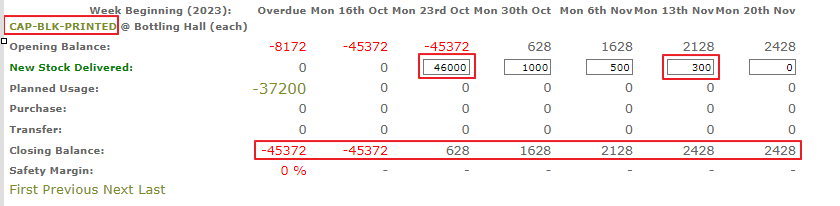

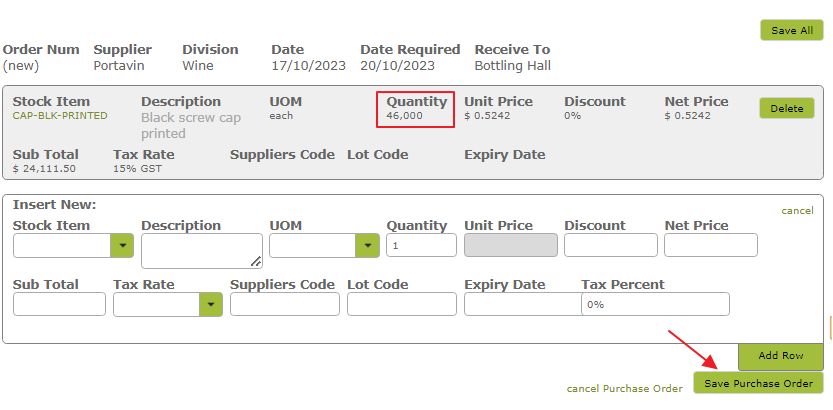

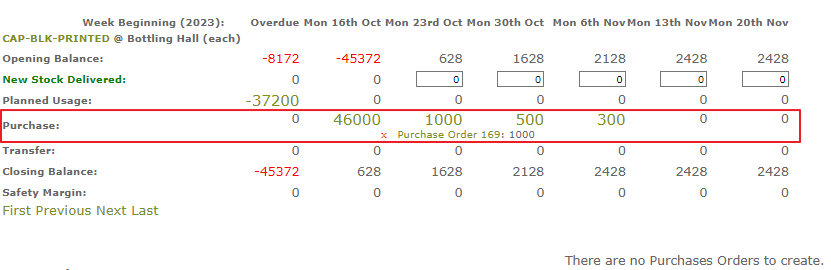

You can use the boxes in the “New Stock Delivered” rows to schedule new Purchase Orders to deliver stock in time for the beginning of that week. Balances will respond to these changes so you can see how adding new purchases will affect your stock levels week by week:

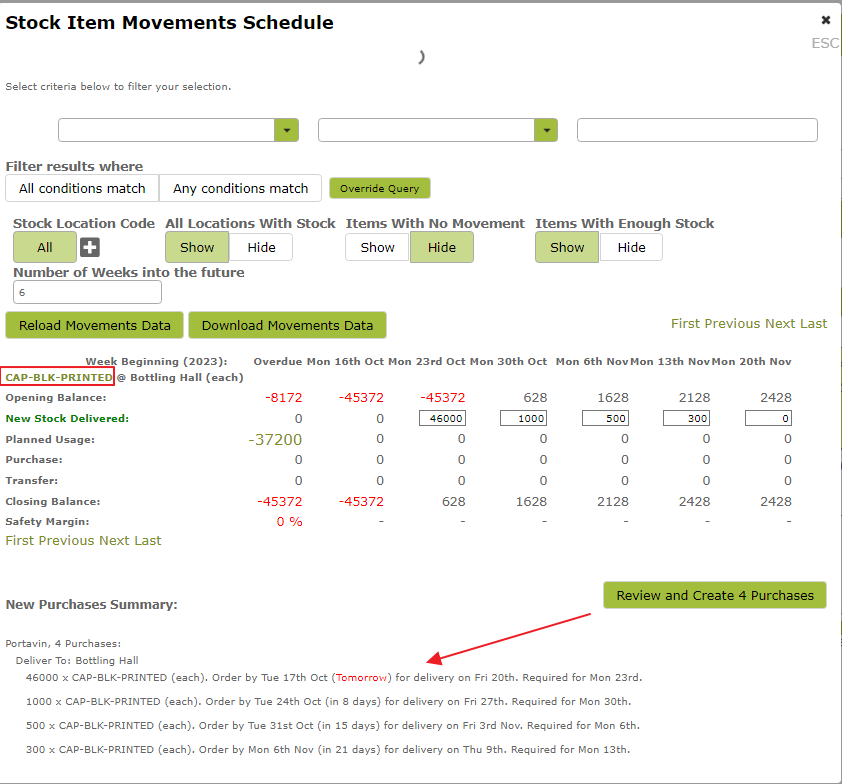

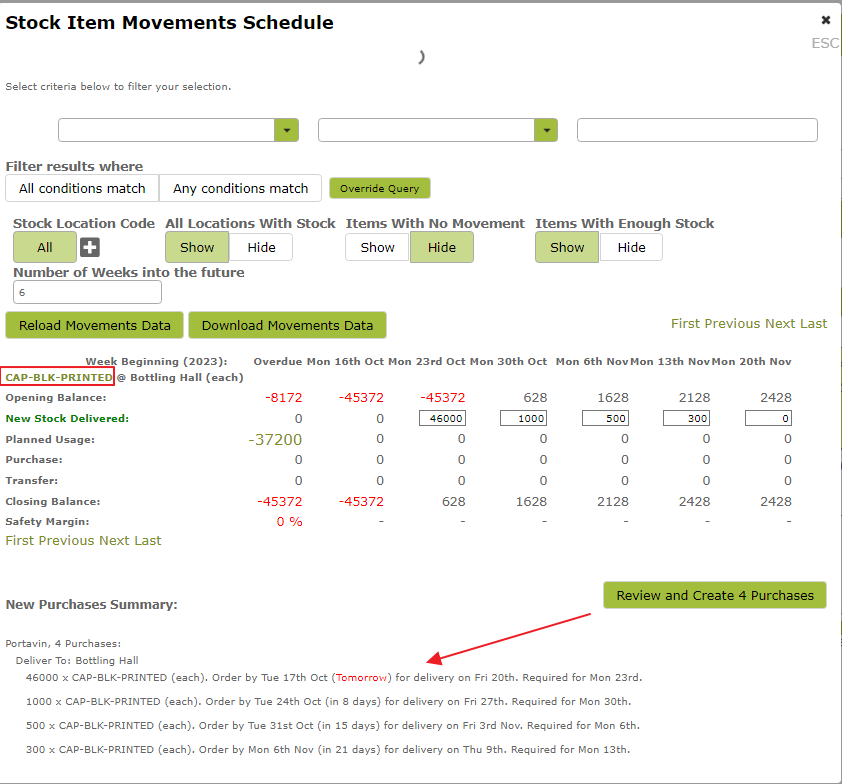

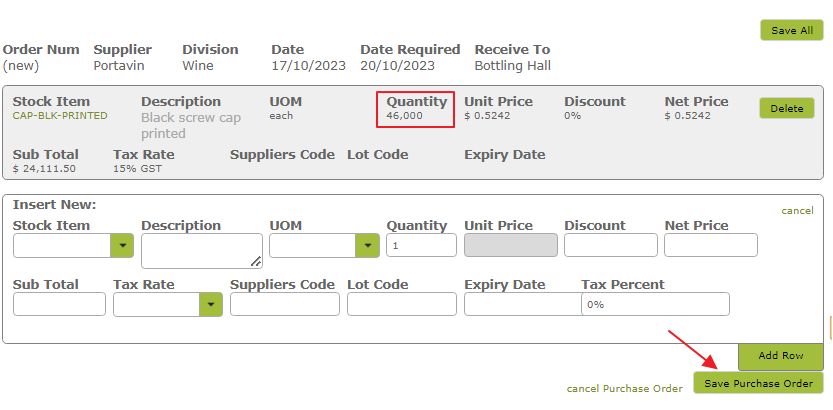

Once you are happy with your planned stock deliveries. You can use the view to create the required Purchases Orders:

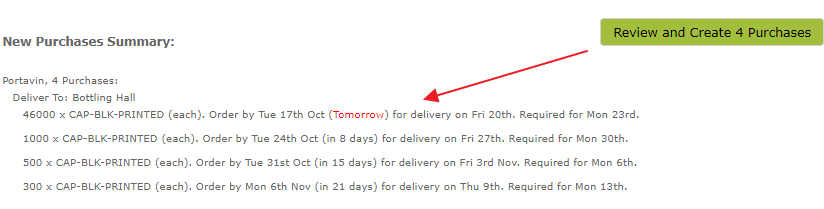

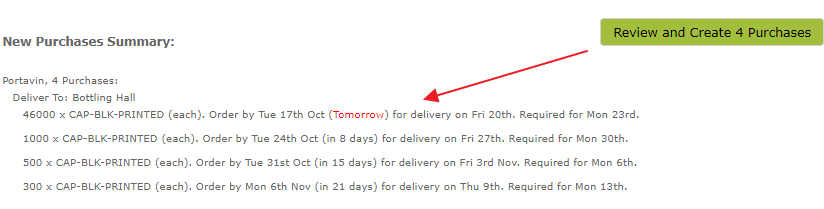

You can see a summary of the new Purchase Orders that are going to be created at the bottom of the Schedule. Vinsight will automatically group purchases together from the same Supplier, and will also take in to account Lead Times defined on each Stock Item:

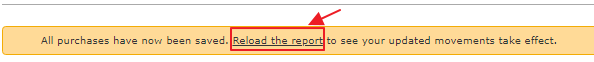

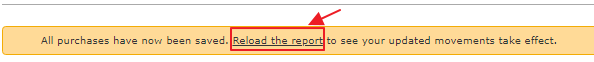

Reloading the report after saving the Purchase Orders will show you the updated Movements Schedule. In this example, two Purchase Orders have been added and now we will not run out of BOXES to use for the weekly Packaging Operations.