Operation Tips (Rack and Return)

Overview

Consider the level of detail you need and the net effect of transactions when recording your operations. The same work-flow can often be entered as a single or as multiple operations, depending on the information you need to track within your organisation. An example, showing how the ‘Rack and Return’ work-flow can be recorded in a single operation is set out here. The same principles operation for any operation.

In this document:

Rack and Return Example

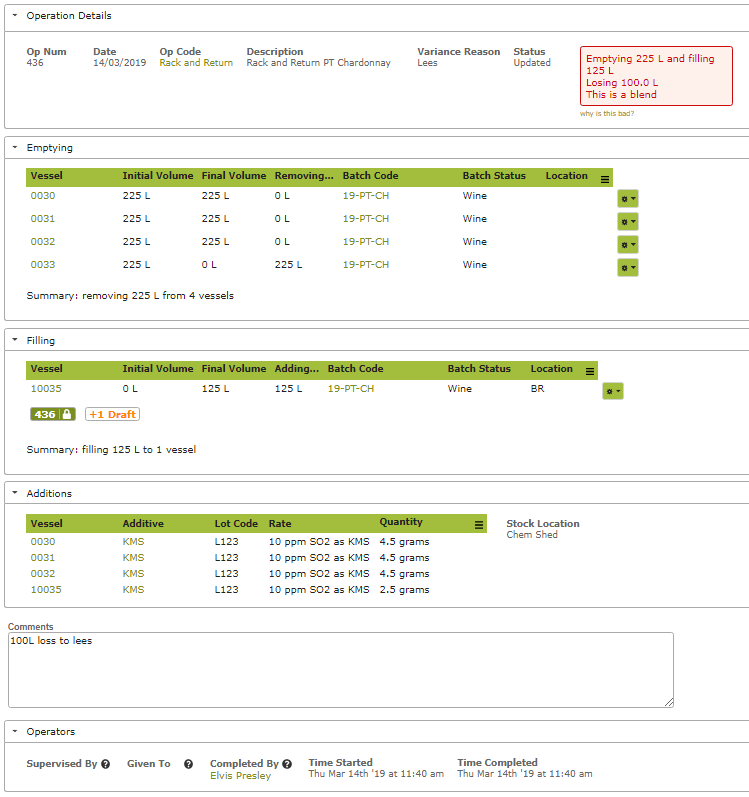

A ‘Rack and Return’ involves a transfer from several barrels into a separate tank and then the return of that same blend to the some of the same barrels with perhaps some SO2 added and a keg or two left over. While you could use two operations to record this workflow (a perfectly legitimate option), it may not be important to your business or your workflow to e.g. record which tank is being used for the racking. If so, you could record this in a single operation as follows:

a) Put all the barrels in the “emptying” section of the operation but ONLY empty the barrel(s) that was not refilled.

b) Put any kegs that were left over in the “filling” area.

c) Optionally add SO2 to the barrels in the “emptying” section if you did additions.